Is PU foam sustainable?

PU foam – an environmentally friendly insulation material

When is an insulation material sustainable? When it’s made of natural products or when it provides long-lasting and reliable insulation? The bottom line in climate protection is how much energy an insulation material saves, thus reducing CO2 formation. Thanks to its excellent insulation values, construction foam will save much more energy after a short time than was needed to produce it. And it has a lifespan of over 30 years.

Every year, about 23 million cans of construction foam are sold in Germany. The lion’s share of this is used for window installation. According to estimates by the Institute for Window Technology (ift), around 80 percent of windows in Germany are insulated with construction foam. However, many cans are also put to use by roofers, painters and plasterers as well as craftsmen in the heating and plumbing industries.

Ecological advantages of PU foam

What are considered to be disadvantages of construction foam?

What alternatives are there?

Ecological advantages of PU foam

Save energy with PU foam

construction foam can help you curb your heating costs. The better an insulation material prevents temperature equalisation between indoors and outdoors, the more heating energy it saves. And the less CO2 is released into the environment. construction foam is one of the most efficient insulation materials for filling building connection joints such as in windows. Even a modern high-tech window is only as good as its joint insulation.

Construction foam insulates the best

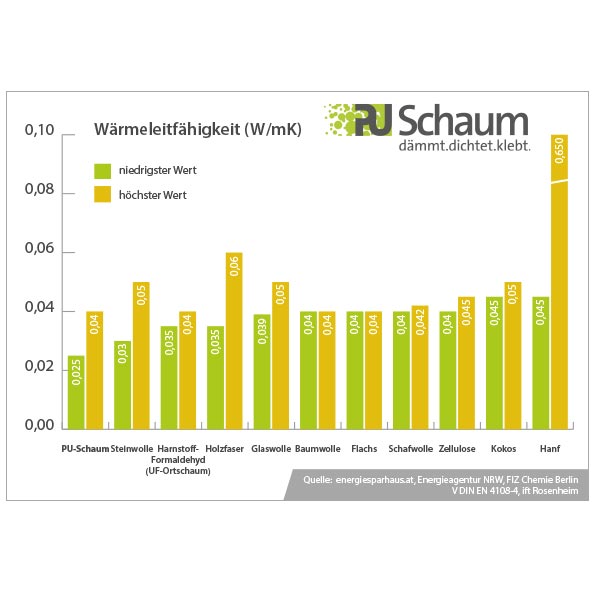

If you compare the different insulation materials for window joints, you’ll see that PU foam has the lowest thermal conductivity and the best insulation properties. In other words: It insulates the best. This is due to its closed, fine-cell structure. This means that many tiny enclosed air bubbles prevent heat and cold from being transferred. In winter the cold stays outside and in summer the heat.

Construction foam fills joints reliably

How much energy an insulation material can actually save also depends on how carefully the joints are filled. Because it expands to about twice its volume after being inserted into the joint, construction foam ensures very good joint filling – especially in places where unevenness needs to be evened out.

In the case of insulation materials that have to be tamped manually, the quality of the insulation depends more on how carefully the craftsman works. Patchily applied insulation wool can cause the wool to settle and leave some areas of the joint with virtually no insulation.

Construction foam is easy to transport

A PU foam can is handy and easy to transport. Depending on the trade, this can be a considerable ecological advantage. When installing composite thermal insulation systems, for example, a single PU foam can replaces an entire bag of cement. Much less energy is needed for its transport than for the cement.

Climate protection: How construction foam saves CO₂

Almost 40% of energy consumption in Germany is attributable to the building sector. In private households, heating and hot water alone require 85% of the energy – and this is where there is huge potential for savings.

If you reduce energy consumption through insulation measures, you’re making an active contribution to climate protection and automatically lowering carbon dioxide (CO2) emissions. It’s important that you also have the joints in the building envelope carefully sealed and insulated.

Whether you’re replacing old windows or renovating the roof, walls, floors or ceilings to improve energy efficiency with external thermal insulation composite systems (ETICS), canned PU foam is needed to insulate the connection joints. This prevents the heat from escaping later so that home-owners can actually reap the energy gains. This is good for the wallet and for the environment.

Bauschaumdosen können fast vollständig recycelt werden

To ensure that the valuable ingredients of used PU foam cans are not lost, a convenient take-back and recycling system is in place throughout Germany, operated by recycling specialist PDR. About 95% of the can is recycled at the plant in Thurnau. 80% of this is even recycled in materials. You can find out how this works and all the ins and outs in our chapter Recycling – a new lease of life for construction foam cans.

You can learn how to return your spent cans for recycling yourself free of charge here.

What are considered to be disadvantages of construction foam?

The ingredient isocyanate (MDI)

One of the main criticisms of PU foam is its ingredient isocyanate, often abbreviated as MDI. MDI can escape in small quantities during the processing phase while the foam is not yet hardened. It’s classified as possibly carcinogenic.

However, the professional associations do not consider the “possibly carcinogenic effect” to be relevant to health, but the possible irritation of the respiratory tract or sensitisation of the skin. Irritation of the respiratory tract is possible after inhalation in concentrations above the occupational exposure limit, whereas sensitisation of the skin is possible when sensitised persons come into contact with fresh foam. This limit value is not exceeded during normal use of a PU foam can. Nevertheless, always ensure good ventilation and protect skin and eyes when working with PU foam.

Cured polyurethane, i.e., solid construction foam, no longer contains free isocyanates and does not emit MDI. It’s environmentally neutral. This is why, for example, rigid PU foams are often used for food transport because of their good insulation properties.

Tightness of construction foam

Some blog posts aimed at interested laypersons assert that PU foam alone cannot be used to make a building connection joint airtight – and that it’s not state-of-the-art according to the RAL standard.

This is true and applies in equal measure to all other insulation materials that are usually mentioned as alternatives in such articles. For example, mineral wool, hemp, sheep’s wool or sprayed cork. After all, these are insulation materials, not sealants. Their task is to ensure that the joint is provided with good thermal insulation. They’re not responsible for a window’s tightness or for fixing it in place.

All insulation materials help seal a joint to a certain extent, but further work steps are always necessary to seal a joint according to the recognised rules of technology. A window is fixed with special window screws.

You can find out more about this in the interview with the German expert for professional window installation Dipl.-Ing. Wolfgang Jehl from ift Rosenheim.

What alternatives are there?

Before PU foam found its way onto building sites in the 1970s, joints were tamped with mineral wool, hemp or tow. Of course, this is still possible today. Wood fibre, glass wool, cotton, flax, sheep’s wool, cellulose, coconut and hemp are also used.

In the comparison of insulation values of these insulation materials, PU foam performs best. In addition, the insulation effect of all materials that are tamped manually also depends on how well and carefully the craftsman works. If the tamping is not done precisely, the wool can settle later. This means that some areas of the joint remain virtually uninsulated.

PU foam, on the other hand, has the advantage that it expands even in the joint. This means that even inexperienced workers can reliably fill a joint.

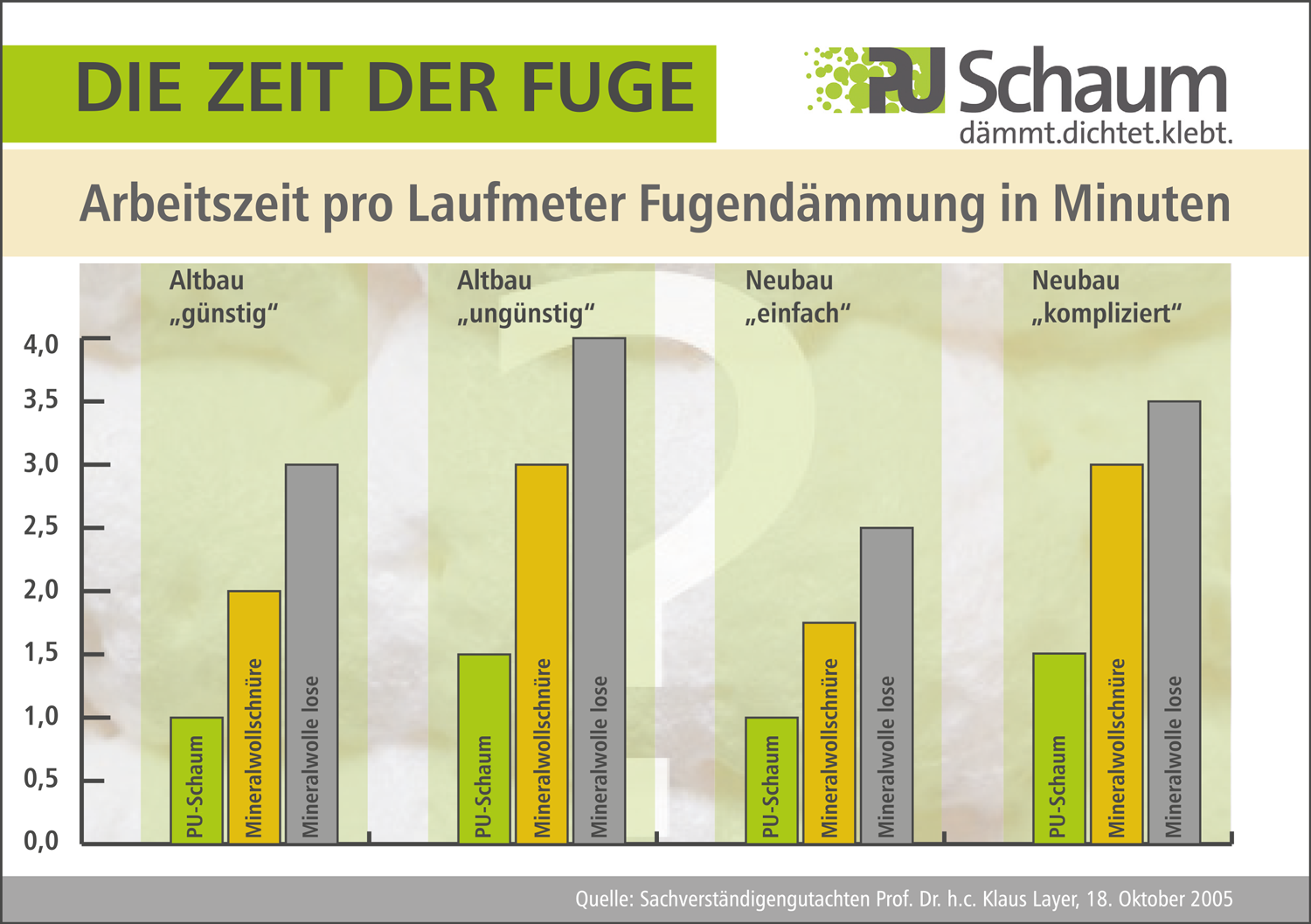

Moreover, it takes much longer to insulate a joint with tamping material. This was found in an expert report that compared the working time per linear metre of joint insulation of PU foam, mineral wool cords and loose mineral wool. Depending on the installation situation, it can take two to three times as long: This is why tamping is also significantly more expensive.

You can download the expert opinion here.

Multifunctional tapes that combine all three sealing and insulating levels are often mentioned as an alternative. In this case, however, it’s essential that the joint width does not vary too much. It has become common practice to install windows with both multifunctional sealing tapes and PU foam.

Blowing agents

Some articles still claim that construction foam cans contain propellant gases such as HFCs or – even worse – CFCs, thus damaging the ozone layer. However, the use of these gases has been history for a long time.

CFCs, which were used initially, were discontinued by the early 1990s because they were suspected of contributing to the depletion of the ozone layer. Subsequent generations (HCFCs and later HFCs) were significantly more environmentally friendly in terms of ozone depletion potential (ODP) and global warming potential (GWP), but still not optimal.

Depending on the manufacturer, these propellants have also been successively replaced over the past 20 – 25 years, often before they were regulated by law. Nowadays, we only use gases that have no ozone depletion effect and minimal global warming potentials. These are the same propellants that are used in household and cosmetic aerosols such as hairspray.

The only relevant disadvantage of the new propellants is their flammability, which is why good ventilation and the avoidance of ignition sources must be ensured, especially when handling PU foam cans. By the way, this applies equally to all household aerosol dispensers.

And just what are the propellants in PU foam good for? The compressed gases have several functions. They generate the necessary pressure so that the contents can be removed in the first place. They ensure the fine-cell foam quality and are responsible for a number of other properties of the foams.