The history of polyurethane

A plastic that can be hard or soft, elastic or rigid, solid or foamy? What initially sounded like a crazy idea quickly took hold. The chemist Otto Bayer, who was born in 1902, developed the first polyurethane in 1937 and registered it for patent. Today, his invention has become an indispensable part of everyday life.

Unbeatable foam

Otto Bayer demonstrates a foam test with polyurethane during a lecture. (Photo from 1952, Source: Bayer AG)

Otto Bayer demonstrates a foam test with polyurethane during a lecture. (Photo from 1952, Source: Bayer AG)

Otto Bayer and his team must have had some inkling of how versatile this material would be at the end of the 1930s. The authors of the patent specification that was used to register polyurethane for patent spoke of a 'Plastic that can be used for various application fields.'

Soft …

The fact that polyurethane could form bubbles during synthesis was discovered by accident. Free carboxylic acid groups in the polyesters that were used react with isocyanate groups to form carboxylic acid amides and carbon dioxide. Today, most polyurethane products are foams.

… and hard

For example, PU hard foams were launched in the 1950s to join the soft foams that had dominated until that time. The fine closed pores of the hard foam ensure its excellent insulating properties combined with a relatively low volume. This is something that manufacturers of refrigerators capitalised on first. Even today, you would be hard put to find a refrigerator that is not insulated with polyurethane foam.

How did assembly foam come to be used on building sites?

Today PU foam is a permanent feature at any building site; however, it took many years before construction foam got to where it is today. Up to the start of the 1970s it was only possible to process polyurethane foams industrially. Then a dosing device was discovered that allowed them to be used directly on building sites.

Three inventions for building sites

In principle, three steps were necessary for this: first of all, the chemists came up with a polyurethane formula that did not need a second chemical hardener components for it to harden; the PU could simply harden when it came into contact with normal humidity in the air. This was the birth of the one-component foam (1C PU foam).

The second step was the development of a valve through which the viscous polyurethane could be pressed without immediately clogging the valve.

And finally, suitable aerosols needed to be developed that had four functions:

- To liquefy the prepolymer in the can,

- To press it from the can with pressure,

- To ensure that the foam expanded after application and also

- To guarantee that the hardened foam had a fine-pore and even structure.

Since then, the construction foam cans have become indispensable on building sites. About 80 percent of all windows and doors are mounted and insulated with PU foam today. Numerous openings in buildings are sealed with PU foam. From a technical point of view, the assembly foams in pressurised cans have been continuously improved. The manufacturers have adapted them to the various application fields.

Specialists for every area

Now, there are mega foams and also low-expansion foams on the market that reach their final expansion volume within seconds after application. This also includes winter foams, which can be used up to - 10 °C, well foams for sealing against non-pressing water or special foams for attachment of door frames.

Low-monomer or monomer-free foams

Low-monomer or monomer-free foams were launched in 2009; these are PU foams whose level of reactive chains in the MDI, which has been classified as harmful, lies below 1 percent or PU foam that no longer contain free isocyanate groups (= MDI) because these have been turned into a neutral urethane skeleton in a preliminary chemical stage.

The foam hardening process is based on reaction-capable silane groups that, once the foam has left the can, react with the ambient moisture leading to the interconnection and therefore the hardening of the applied PU foam. MDI-reduced or MDI-free foams are generally used in the hobby sector; professionals prefer the classic MDI-based PU foams for their work.

What are polyurethanes?

Polyurethanes (PU) are a highly versatile group of plastics that we find wherever we look today. Depending on its formula, PU can be flexible or rigid, hard or soft, which means that it can be used for instance for effective thermal and cold insulation, car bumpers, furniture upholstery, car seats or mattresses, and of course in construction foam cans.

The basis for various products

Polyurethane is also used to insulate electrical or electronic parts. Even state-of-the-art high-performance paints, sports shoes, flooring or medical prostheses all have a common base: polyurethane.

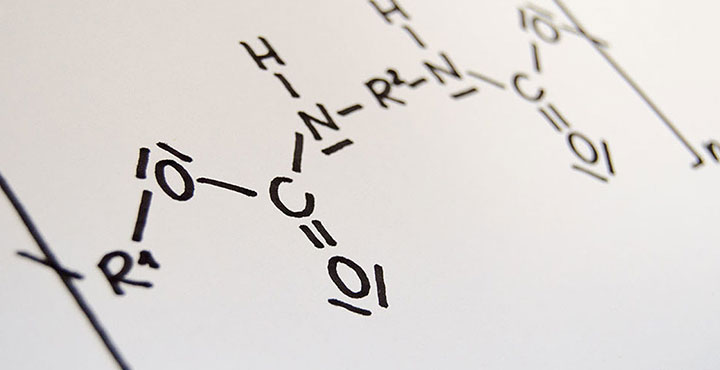

This versatile plastic is created by the principle of polyaddition using isocyanates. The name 'polyurethane' is derived from the main urethane group NH-CO-O that is formed.

PU's key to success lies in its almost legendary adaptability: polyurethanes can be flexible or rigid, hard or soft – and that in every possible degree depending on requirements. Even its patent specification in 1937 described it as a 'Plastic that can be used for various application fields.'

In addition to a multitude of industrial applications, it has also been an indispensable material on building sites since the 1970s. The PU foam can allowed the PU foam to be applied directly on site as required. Construction foam or assembly foam (as PU foam is also called) is suitable for mounting, sealing and insulating.

![[Translate to Englisch:] Bauschaum [Translate to Englisch:] Bauschaum](/fileadmin/PU-Schaum-Center/PU-Schaumarten/img_PU-Schaumarten_bauschaum_produkt_viele_namen.png)

![[Translate to Englisch:] PU im Alltag [Translate to Englisch:] PU im Alltag](/fileadmin/PU-Schaum-Center/Wissenswertes/img_PU_im_alltag.jpg)

![[Translate to Englisch:] Energie sparen mit PU-Schaum [Translate to Englisch:] Energie sparen mit PU-Schaum](/fileadmin/PU-Schaum-Center/Energie_Nachhaltigkeit/img_energie_sparen.jpg)