1C PU foam – the number one

1-component PU foam cans have a market share of 80 percent and therefore dominate the construction foam market in Germany. The foam hardens by reacting with the ambient moisture - i.e. with the humidity in the air and the moisture in the construction materials.

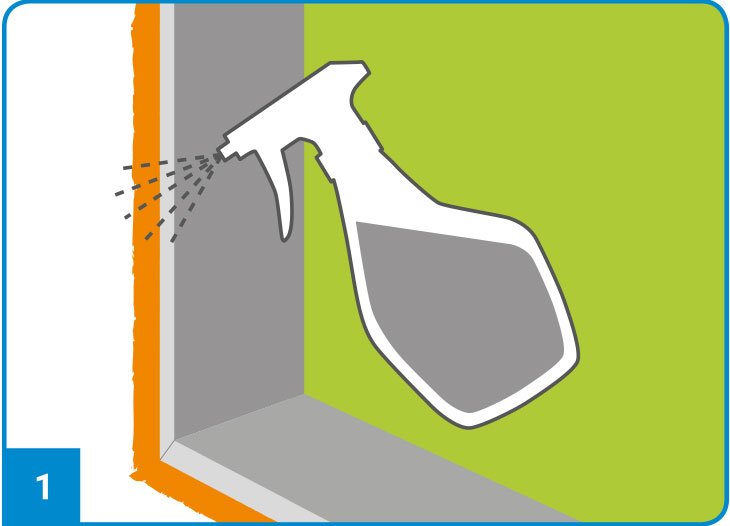

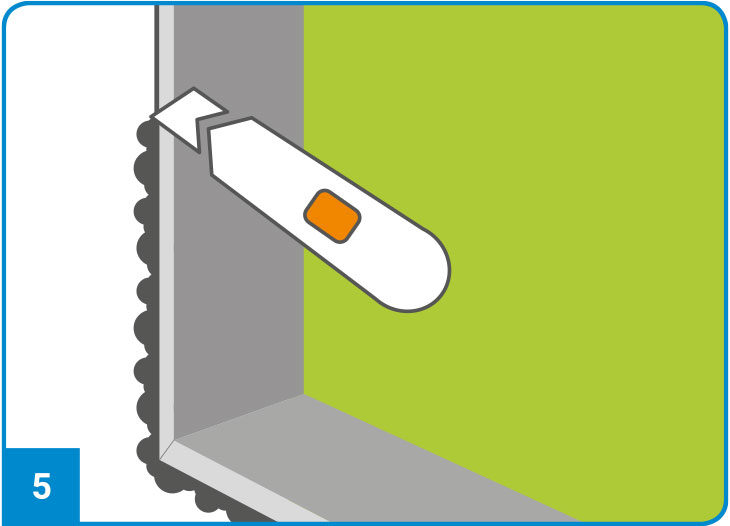

1C foam hardens from the outside (where moisture impacts first) inwards. A classic application for 1C construction foam is insulating windows. It does not require any further chemical components to harden. It is recommended spraying the connection surfaces with water before and after applying the foam to accelerate the hardening process and improve the quality.

You should know this simple trick

For instance, a water sprayer, like those used for house plants, can be used. This is especially helpful, if you are filling tight cavities with PU foam, for example deeper shafts or a pipe. There is often not enough ambient moisture in tight spaces.

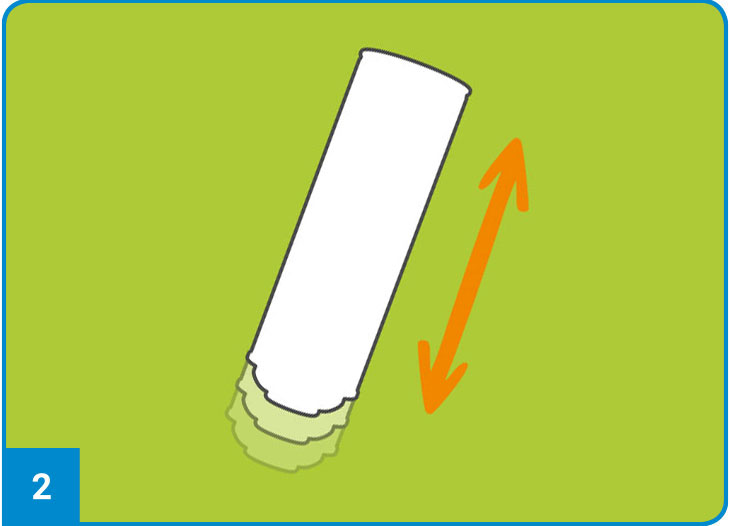

It is recommended working in layers and always spraying water onto a fresh layer of foam before adding more foam. This ensures enough moisture and the foam hardens reliably as required.

What happens, if there is not enough moisture for the construction foam?

In the best case, the 1-K foam simply requires longer until it is completely hardened. In the worst case, the inner core will remain soft initially. If the humidity increases at a later date, the core can still react and expand afterwards.

Usage instructions for

1C PU foam cans with an adapter and safety valve

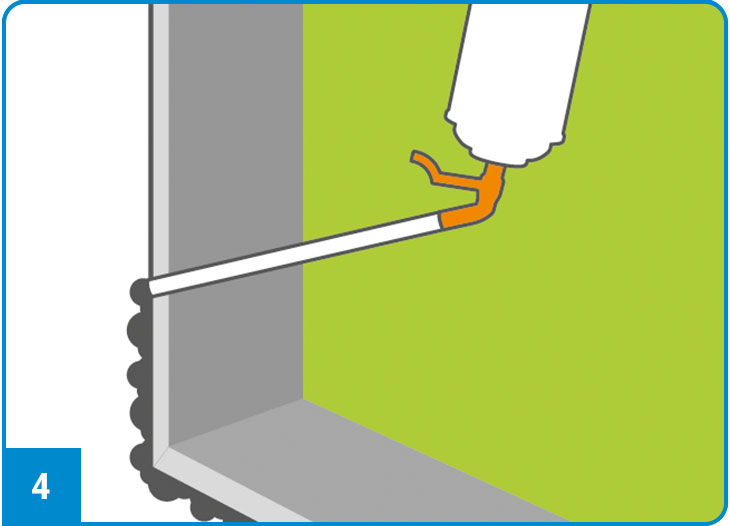

The installed parts need to be correctly aligned, wedged and/or screwed into position on firm, dust and grease-free surfaces. The adjacent surfaces need to be covered to protect them (e.g. with masking tape). We recommend moistening the surface slightly where the foam is to be applied.

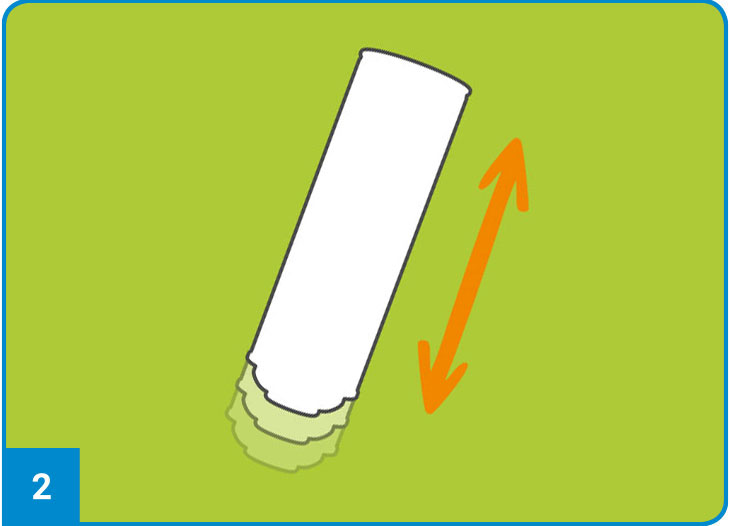

Before use and after application breaks, the can must be shaken well and, when working with foam, ensure that the workplace is ventilated adequately. Please observe the information provided by the manufacturer about processing and ambient temperatures.

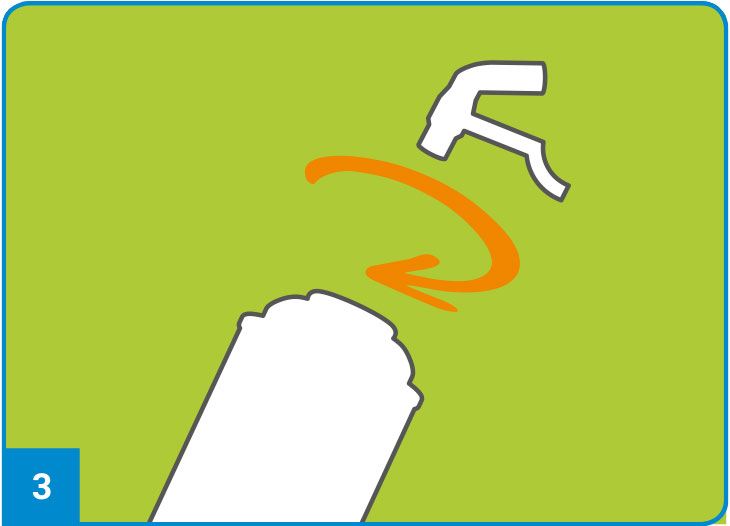

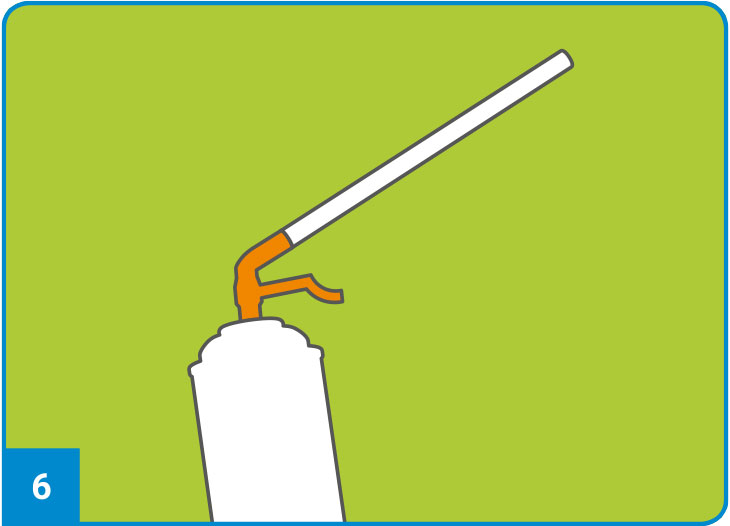

Remove the can lid, attach the adapter to the valve and screw tight. Then hold the can so that the valve is facing downwards. Now the foam can be applied.

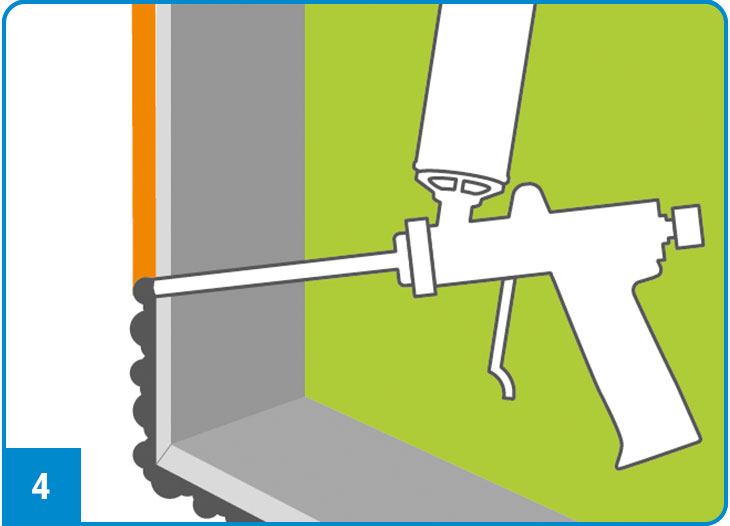

Apply sparingly because the volume of the foam will expand greatly. The tilting valve can be opened and also controlled by applying pressure onto the adapter with your finger.

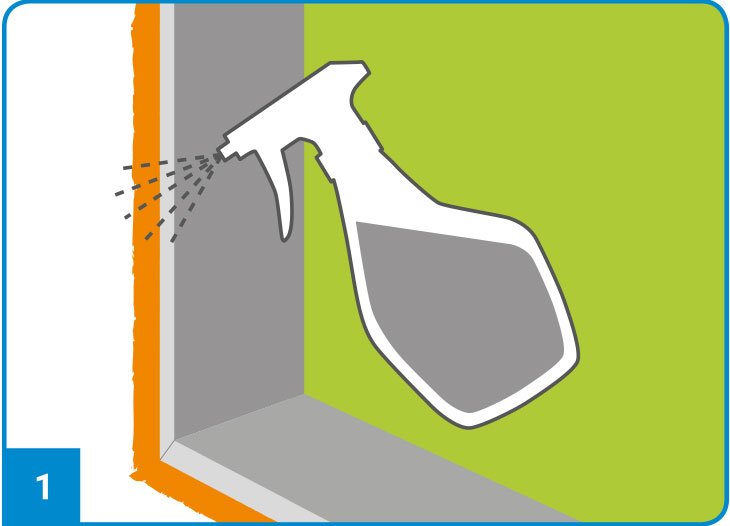

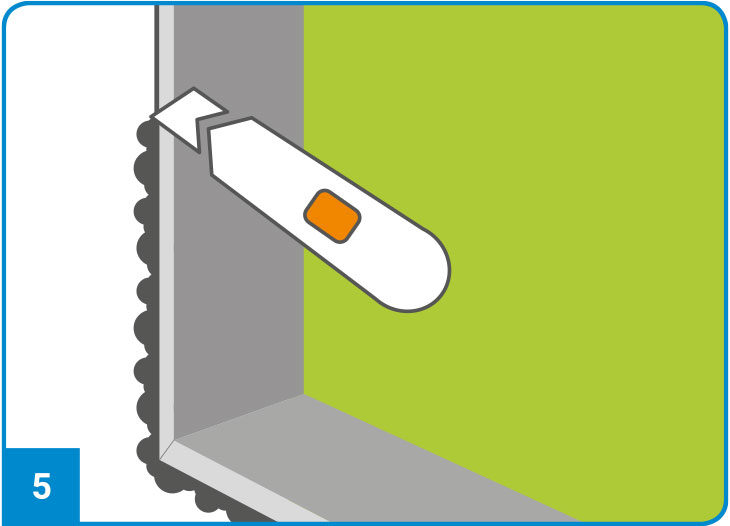

The PU foam will harden as a result of the moisture in the environment and the air. The foam will spread automatically and fill the hollow spaces, and therefore should not be cut or painted over when fresh. Corrections can only be made and excess foam cut off or sawn off after it has hardened.

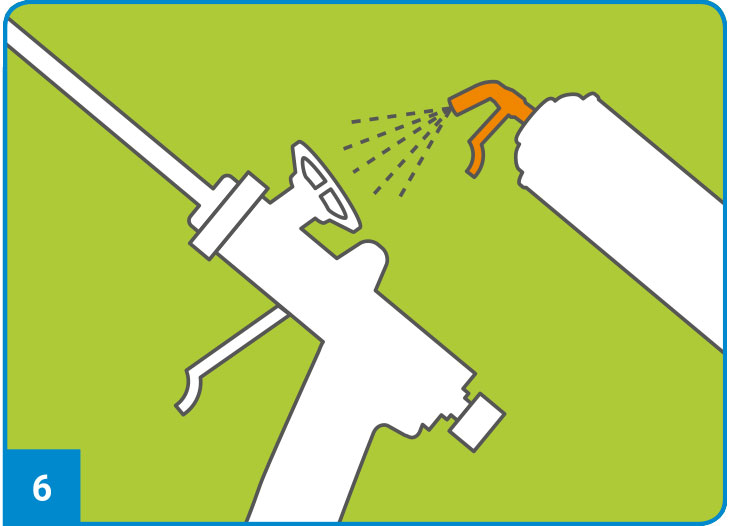

If the contents of the can have not been completely used up, clean the can valve and the adapter tube with a PU foam cleaning agent so that it is possible to use the can again.

Spent PU foam cans and any residues inside are recycled to approx. 95% which saves resources and CO2. PDR – the high-tech recycling company, the leading European manufacturer0 of PU foam cans – collects the spent cans from professional users free of charge. DIY stores and recycling depots will take back individual cans. Online search of the acceptance points or collection orders at www.pdr.de or call: 0800- 7836736.

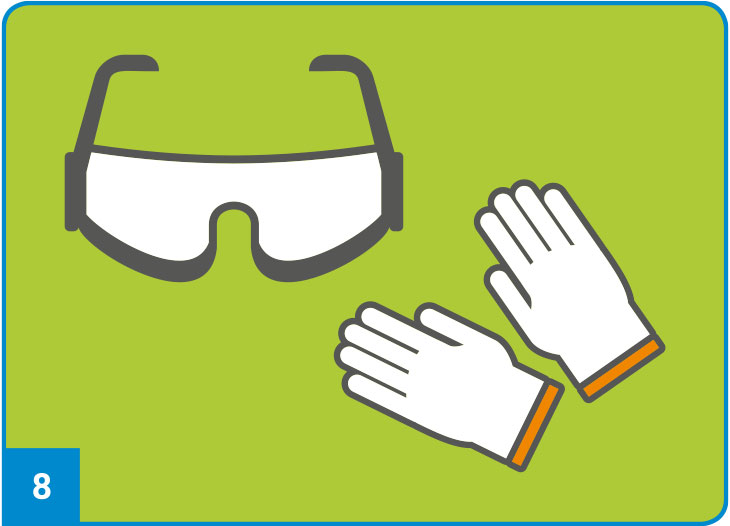

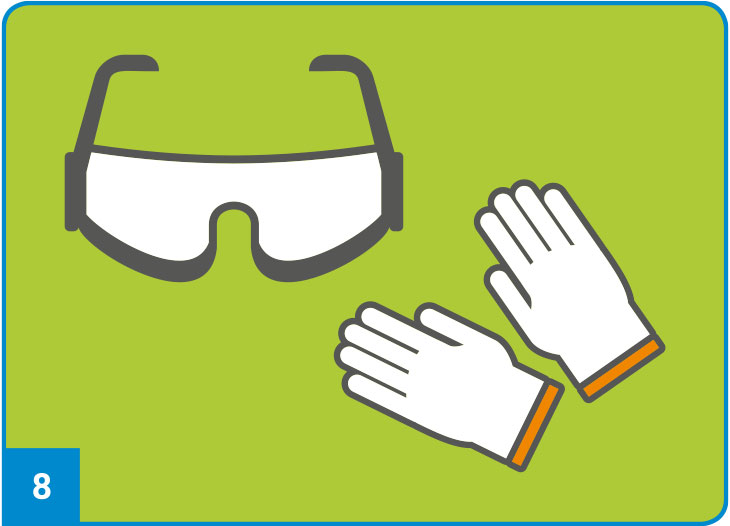

Always wear gloves when working with PU foam products because the fresh foam is highly adhesive and can only be removed mechanically after it has hardened. Likewise, wear goggles. For more information about product safety and handling, please refer to the product safety data sheet and the manufacturer's product label.

To the download: Processing information (PDF)

Note: The general processing information stated here is not binding. For binding information about processing, handling and occupational safety, please refer to the product data sheets for the respective PU foam issued by the manufacturer and the labels on the PU foam cans.

Processing information for

1-K gun PU-foam

The installed parts need to be correctly aligned, wedged and/or screwed into position on firm, dust and grease-free surfaces. The adjacent surfaces need to be covered to protect them (e.g. with masking tape). We recommend moistening the surface slightly where the foam is to be applied.

Before use and after application breaks, the can must be shaken well and, when working with foam, ensure that the workplace is ventilated adequately. Please observe the information provided by the manufacturer about processing and ambient temperatures.

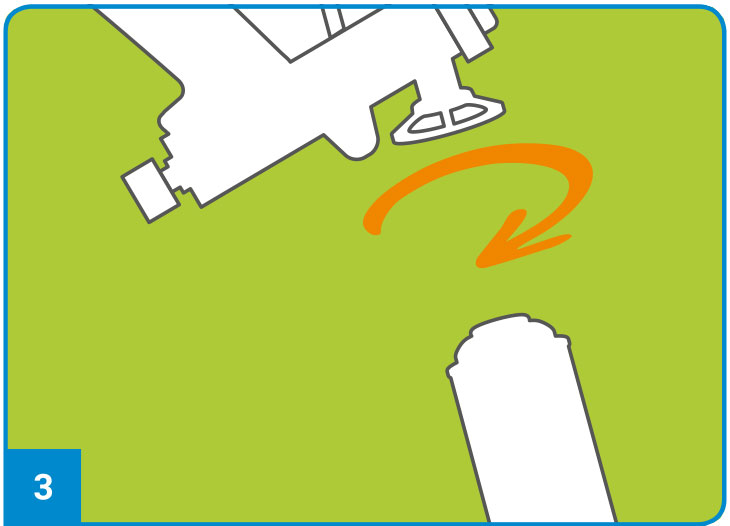

Remove can lid, screw the PU foam can with the valve facing upwards onto the PU gun; do not screw on too tightly. Then apply the foam.

The PU gun should remain on the can until the rest has been used. Soiling caused by leaked foam must be carefully removed from the thread and the valve with a suitable cleaning agent. Then attach a new can to the PU gun immediately, otherwise it will become sticky. Using a PU gun means that the foam can be applied economically.

The PU foam will harden as a result of the moisture in the environment and the air. The foam will spread automatically and fill the hollow spaces, and therefore should not be cut or painted over when fresh. Corrections can only be made and excess foam cut off or sawn off after it has hardened.

The PU gun must always remain on the can. Please use generous amounts of a suitable special cleaning agent to clean the PU gun. The can should never be removed from the adapter with force. If a PU gun can no longer be used because it is soiled, the applicable parts should be dismantled and cleaned, and a new gun should be used.

Spent PU foam cans and any residues inside are recycled to approx. 95% which saves resources and CO2. PDR – the high-tech recycling company, the leading European manufacturer0 of PU foam cans – collects the spent cans from professional users free of charge. DIY stores and recycling depots will take back individual cans. Online search of the acceptance points or collection orders at www.pdr.de or call: 0800- 7836736.

Always wear gloves when working with PU foam products because the fresh foam is highly adhesive and can only be removed mechanically after it has hardened. Likewise, wear goggles. For more information about product safety and handling, please refer to the product safety data sheet and the manufacturer's product label.

To the download: Processing information (PDF)

Note: The general processing information stated here is not binding. For binding information about processing, handling and occupational safety, please refer to the product data sheets for the respective PU foam issued by the manufacturer and the labels on the PU foam cans.

![[Translate to Englisch:] 2 K Schaum [Translate to Englisch:] 2 K Schaum](/fileadmin/PU-Schaum-Center/PU-Schaumarten/img_PU-Schaumarten_2-K-PU-Schaum.png)

![[Translate to Englisch:] Klebeschaum zum Kleben und Dämmen [Translate to Englisch:] Klebeschaum zum Kleben und Dämmen](/fileadmin/PU-Schaum-Center/PU-Schaumarten/img_PU-Schaumarten_PU-Klebeschaum_Kleben_Daemmen.png)

![[Translate to Englisch:] Fensterschaum [Translate to Englisch:] Fensterschaum](/fileadmin/PU-Schaum-Center/PU-Schaumarten/img_PU-Schaumarten_Fensterschaum.png)