PU valves – you should know these simple facts

Construction foam only came to the construction site when a valve was developed, through which the viscous prepolymer could be pressed without sticking immediately. You can find out here how the valves are constructed – and the three most common reasons why a valve sometimes does not work properly

How valves on construction foam cans work

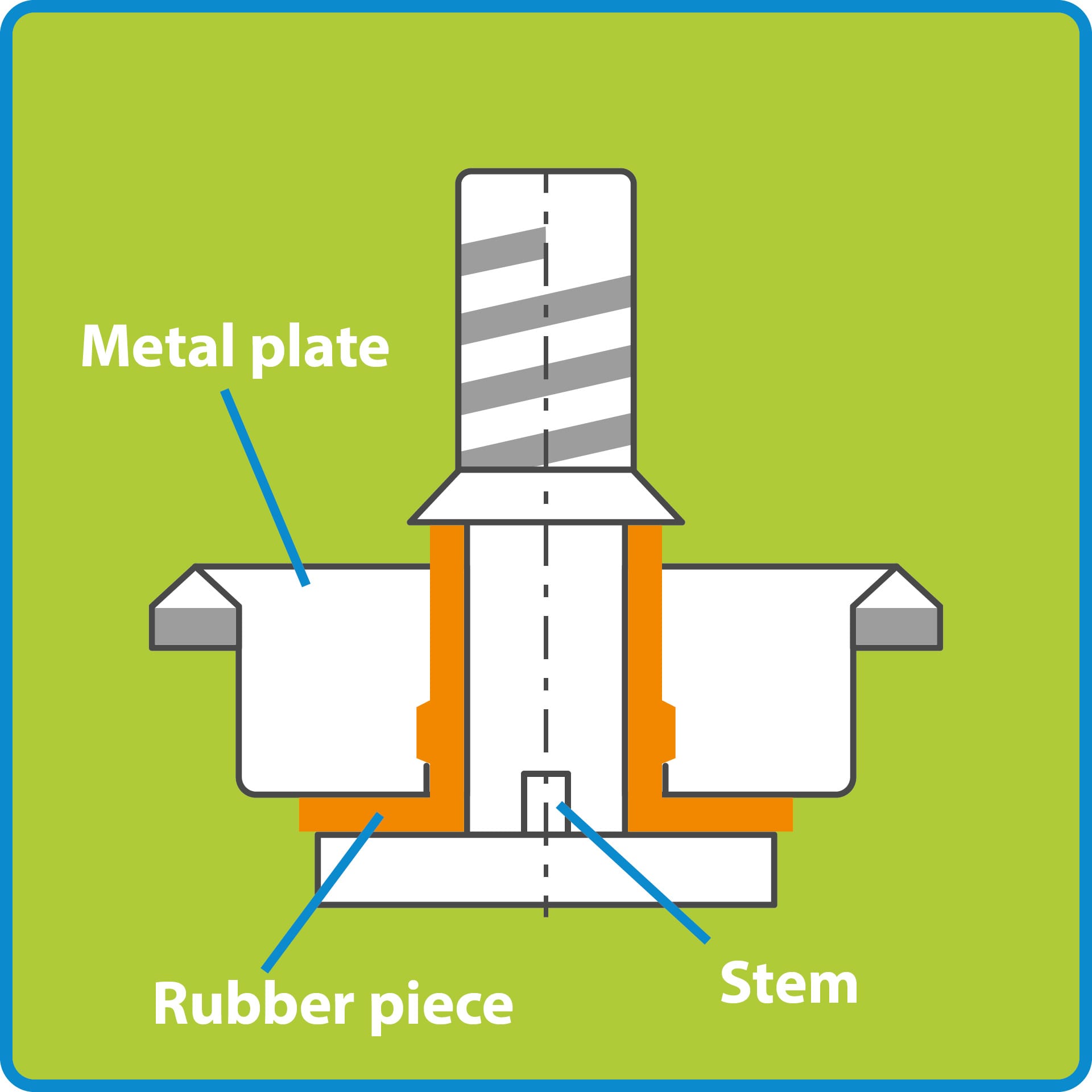

Traditionally, a PU valve consists of three parts: the metal plate, a rubber piece for sealing and a short plastic tube with a thread (stem), onto which the gun or the adapter tube is screwed.

The metal plate is the upper end of the construction foam can. The rubber piece seals it. It keeps the compressed gas in the can and prevents moisture from penetrating. It also closes the valve after use.

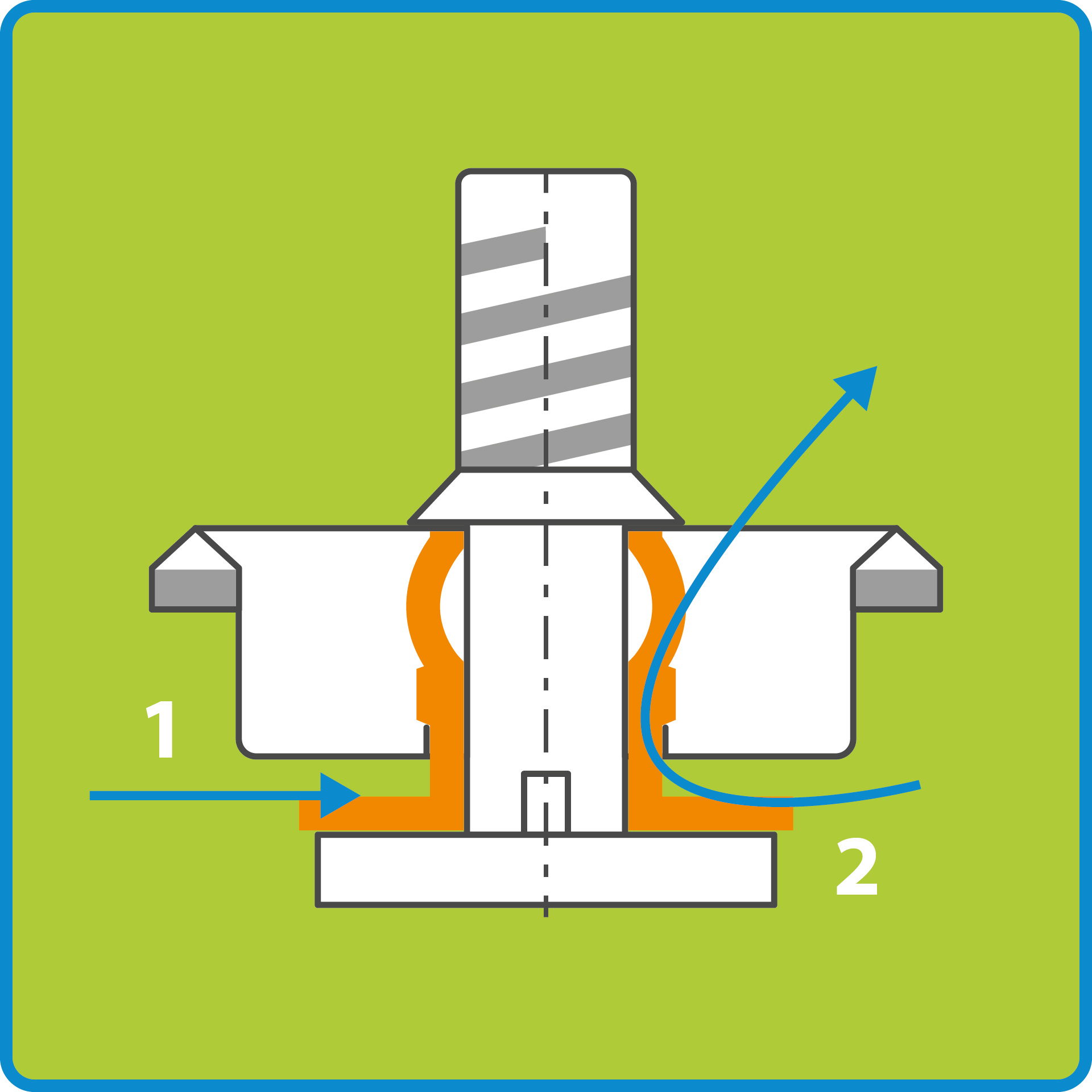

The valve opens when you screw your PU foam gun or the adapter tube supplied onto the stem and, by doing so, press down or tilt the valve. Both open the rubber seal in the can, so that the foam can escape between the rubber and the stem.

Closed valve:

![[Translate to English:] Geschlossenes Ventil [Translate to English:] PU-Ventile, PU-Schaum, Tipps, PU-Schaum-Center, Schaumdosen, Stem, Gummidichtung](/fileadmin/PU-Schaum-Center/PU-Schaum_in_der_Praxis/Ventile/pu-ventil_01_hq.jpg)

The stem and rubber seal are close together.

Open valve:

![[Translate to English:] Geöffnetes Ventil [Translate to English:] PU-Ventile, PU-Schaum, Tipps, PU-Schaum-Center, Schaumdosen, Stem, Gummi, Schaum](/fileadmin/PU-Schaum-Center/PU-Schaum_in_der_Praxis/Ventile/pu-ventil_02_hq.jpg)

The stem is depressed. There is a gap of about 2.5 mm between the rubber and the stem, through which the foam (arrows) can emerge.

Open valve:

![[Translate to English:] Geöffnetes Ventil [Translate to English:] PU-Ventile, PU-Schaum, Tipps, PU-Schaum-Center, Schaumdosen, Steam, Gummi, Schaum](/fileadmin/PU-Schaum-Center/PU-Schaum_in_der_Praxis/Ventile/pu-ventil_03_hq.jpg)

The stem is tilted. On one side, between the rubber and the stem, there is a gap through which the foam (arrow) can exit.

The three most common reasons why a valve doesn't work properly

- The valve is glued

This can happen for the following reason: the construction foam can was stored or transported lying down and not standing up. That is why the stem and the rubber seal are glued together.

Tips for the correct storage and transport of PU foam cans can be found here

- The can has been stored too long and the can contents are already too viscous to pass through the valve.

- It is the foam gun

What happens when the can valve is glued?

Glued valve: the foam escapes laterally (arrows)

- The valve does not open

In the best case, it simply does not open when a gun or adapter is attached. - The foam sprays out from the side

This is a greater problem if there is an opening between the rubber and the metal plate. Then the foam does not pass through the tube, but emerges from the side. A so-called side sprayer is formed. - 3. The worst case: the stem breaks off

With an adapter foam, the plastic thread (stem) can break off if the adapter tube is over-tightened. If you then try to open the valve by force, it can be pressed into the can. The result: the entire can contents spray out uncontrollably!

You should NEVER, NEVER, NEVER handle a can with a glued valve with a lot of force or even with pointed objects.

Be sure to avoid this mistake!

It can also be the gun – the three most common reasons

The valve is not always to blame if no foam comes out of the can or if the foam quality leaves something to be desired. It may also be due to the gun used.

1. The PU gun does not fit the can

The PU gun may not fit the construction foam can. The different manufacturers use different valves and adjust their foam guns accordingly. If your foam gun does not fit the can thread, the valve will either not open at all or do so only partially. The latter means: very likely only a little foam comes out of the can and the foam quality suffers.

Therefore, always make sure that you use the right foam gun.

2. The spray pipe is clogged

If the gun fits the PU can and still no foam comes out from the front, the gun itself is probably glued. This happens, for example, if the gun was not cleaned properly after the last use and old foam now clogs the spray tube.

We have compiled tips for cleaning the foam gun for you here

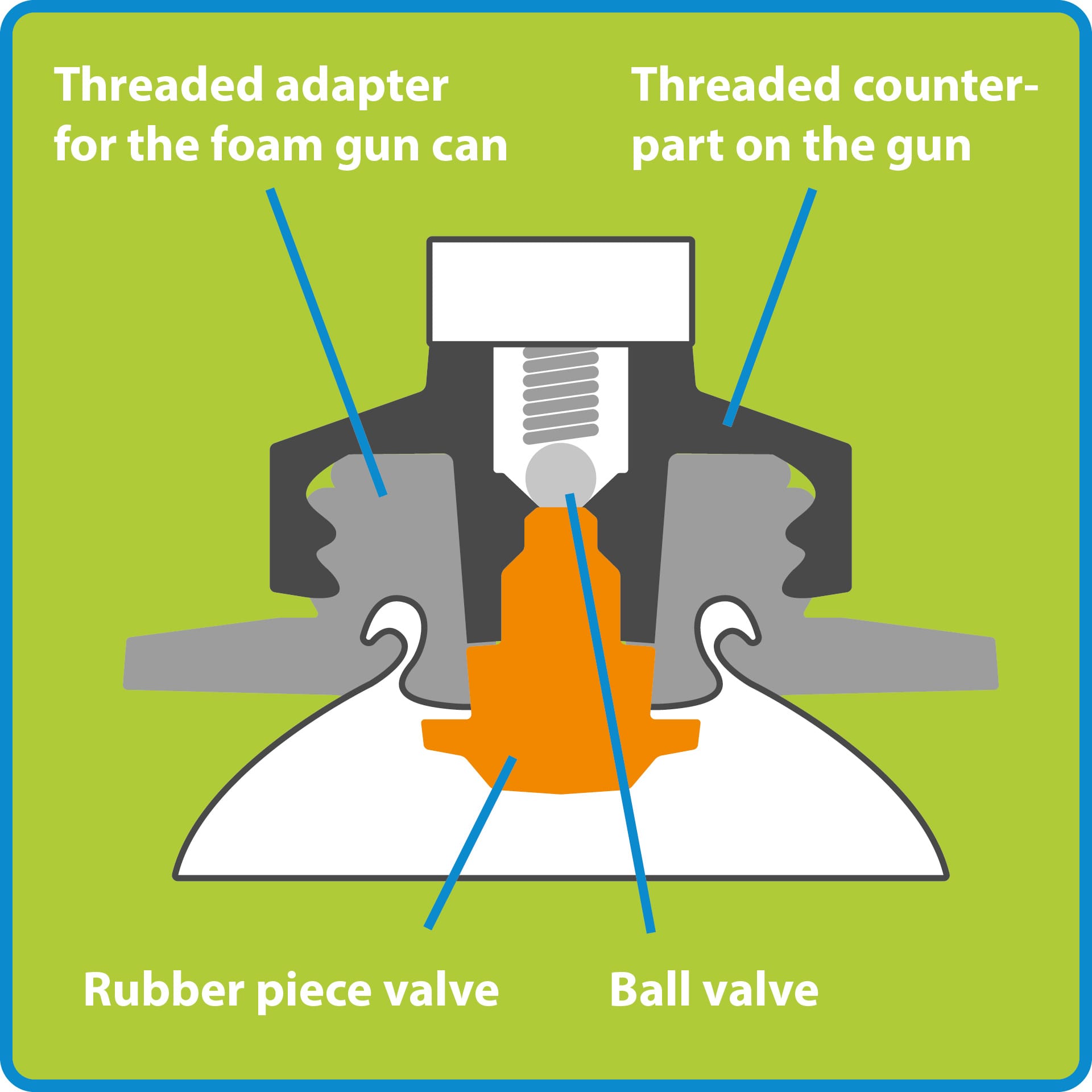

3. The ball valve is glued

The ball valve in the adapter basket can also be glued. It should seal the gun, so that the gun contents do not foam out after unscrewing the can. The small ball is not opened mechanically by screwing on, but by the inner pressure of the can. If it is glued, the pressure is not enough to release it.

How to fix this error

Simply press the small ball down with a thin, but not pointed, object and release the glue.

![[Translate to Englisch:] PU-Schaumarten [Translate to Englisch:] PU-Schaumarten](/fileadmin/PU-Schaum-Center/PU-Schaumarten/img_PU-Schaumarten_bauschaum_produkt_viele_namen.png)

![[Translate to Englisch:] Bauschaum entfernen [Translate to Englisch:] Bauschaum entfernen](/fileadmin/PU-Schaum-Center/PU-Schaum_in_der_Praxis/img_Bauschaum_entfernen.jpg)

![[Translate to Englisch:] FAQ PU-Schaum [Translate to Englisch:] FAQ PU-Schaum](/fileadmin/PU-Schaum-Center/PU-Schaum_in_der_Praxis/img_Praxis_FAQ.jpg)